Working with custom Axial Shape Tools

Custom axial shape tools are generated from a curve drawn from points on a 2D plane. Common tool attributes, such as tool name, tool number, etc., are the same for all subtypes of cutting tools. For example, below is the code for creating a custom axial shape tool in a spherical group of milling tools.

//C#

//importer is an instance of IMTI_MachiningToolsImportLibrary

var tool = importer.CreateCustomAxialShapeTool();

tool.ToolGroup = TMTI_AxialToolGroup.tgSpherical;

tool.OverallLength = 100;

tool.SetName("My Custom Spherical Mill Tool");

tool.SetIdentifier("s001");

tool.SetTeethsCount(2);

tool.SetMagazineNumber(1);

tool.SetToolNumber(1);

tool.SetUnits(TMTI_LinearUnits.luMillimeter);

tool.SetDurability(70);

tool.SetMaxPlungeAngle(90);

var rcv = tool.BeginGeneratrix();

TST2DPoint p = new TST2DPoint() {X = 1, Y = 1};

TST2DPoint pc = new TST2DPoint() {X = 0.0359, Y = 7.3301};

rcv.SetSpanType(TMTI_CurveSpanType.csfWorking);

rcv.StartCurve(p);

p.X = 6; p.Y = 5;

rcv.ArcTo(pc, p, 6.4031);

p.X = 6; p.Y = 25;

rcv.CutTo(p);

rcv.SetSpanType(TMTI_CurveSpanType.csfNonWorking);

p.X = 6; p.Y = 30;

rcv.CutTo(p);

p.X = 7.5; p.Y = 40;

rcv.CutTo(p);

var toolings = tool.GetToolingPoints();

toolings.ToolContactPointType = TMTI_AxialToolContactPointType.cpCustomPoint;

toolings.ToolContactPointsCount = 1;

toolings.ToolingPointCount = 1;

toolings.ToolingPointType[0] = TMTI_AxialToolToolingPointType.tpCustomPoint;

toolings.ToolingPointShift[0] = 1.5;

toolings.ToolingPointLengthCorrectorNumber[0] = 1;

toolings.ToolingPointRadiusCorrectorNumber[0] = 1;

var cond = tool.GetCuttingConditions();

cond.CuttingSpeedMode = TMTI_CuttingSpeedMode.csmRPM;

cond.RotationsPerMinute = 100;

cond.SpindleGearRange = 1;

cond.RotationDirection = TMTI_RotationDirection.rdCW;

cond.FeedUnits = TMTI_FeedUnits.perMinute;

cond.FeedValue = 100;

int tubesCount = cond.Coolant.TubeCount; //20

cond.Coolant.TubeIsOn[0] = true;

cond.Coolant.TubeIsOn[1] = false;

cond.Coolant.TubeIsOn[2] = true;

//after setting the properties, add this tool to your tool library instance

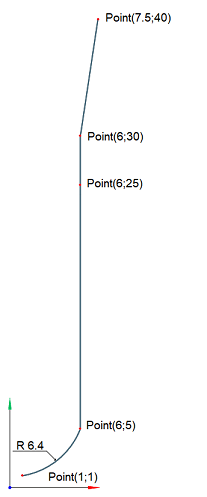

Сurve result view:

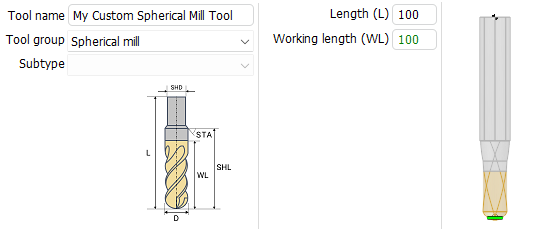

Code execution result:

Helpful links:

- How to work with shaped tools in the CAM interface

- Preparing the machining tools import api environment

- GitVerse: Machining tool import API examples